Used on bk 11and tiodize type i to harden coating for high durability and handling.

Black anodized aluminum reflectivity.

We are looking to coat the inside of a optical cavity.

Used to control ir reflectance on aluminum.

Optical black anodize martin black.

High temperature version of ultra ve 17.

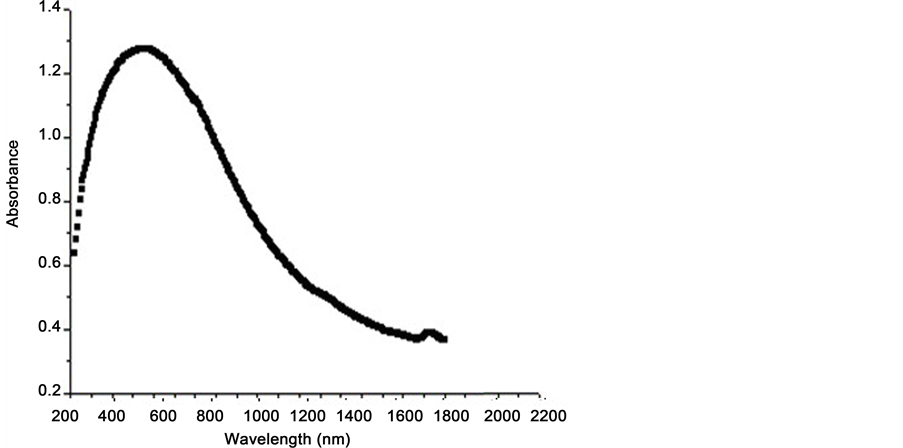

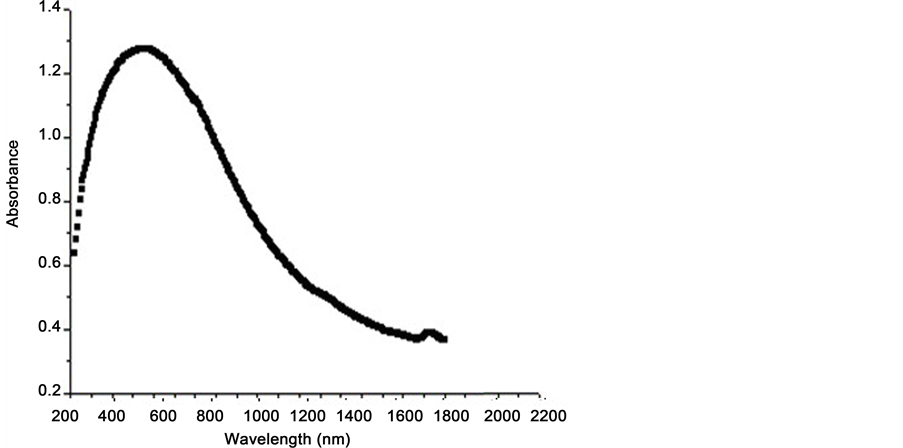

Reflectance of various black materials that may be used to minimize unwanted reflections over a wavelength range.

I believe it is an anodizing process that produces a non reflective surface on aluminum.

Flat black spray paint.

In other words it s still a good idea to get aluminum anodized regardless of whether painting is to intended place or not.

I am looking for a source for martin black.

An ongoing discussion from 2000 through 2019.

Sdn 0003 26 report on ir reflectance of anodized samples.

There s a trick to this when painting aluminum though.

This report describes near ir reflectance measurements of a number of anodized aluminum samples to determine with some degree of control the degree to which various anodizing processes produce black coatings in the infrared.

David k last name deleted for privacy by editor calgary ab.

Optical black keeping your black anodized components black while improving absorbance and reducing reflectivity in optical pathways by 85 back to blog aluminum components and housings used for optical products are oftentimes subject to stray light strong uv light or outgassing when used in a vacuum with high intensity light.